This language is a textual based language. Structured Text is a high-level language that is like Basic, Pascal and “C”. So the programming language for a PLC changes from manufacturer to manufacturer.

PLC programming language, the programmer codes in the chronological order. The user enters lines of code that execute sequentially, evaluate specific functions, boolean checks, and energize appropriate outputs of the PLC.

Ladder diagram (LD) Ladder diagram is the universal programming language of PLC. It has a short abbreviation as LD and also known as Ladder Logic. And it is one of the oldest programming languages for PLC.

LD is a visual programming language, so it is easier to learn than other PLC languages. PLCs from different manufacturers can be programmed in various ways. It is also known as ladder logic. With a few exceptions, a program written in one format can be viewed in another.

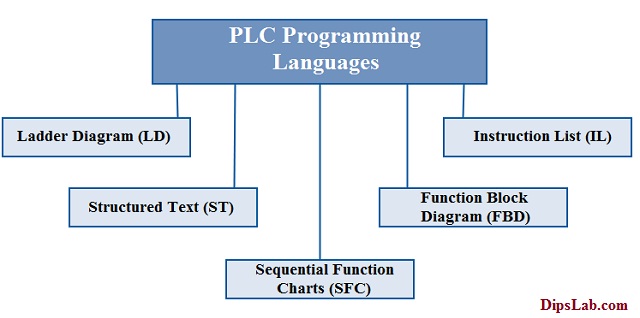

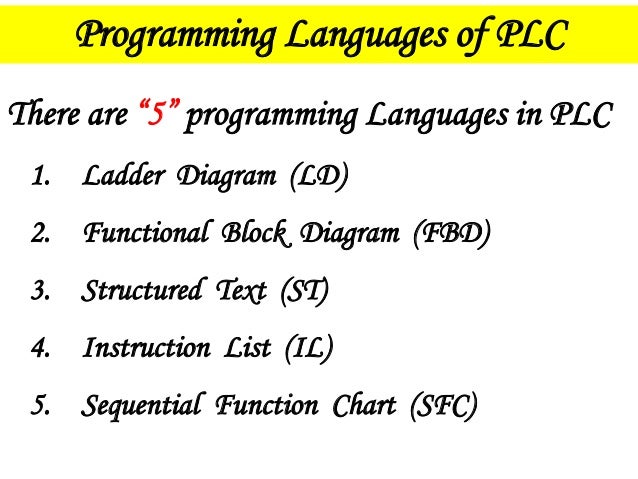

Each one of these languages has advantages, weaknesses, and best use cases. The controllers that are used in industrial automation need to be programmed to perform certain tasks like moving products or sorting them. Function Block Diagram.

In industrial automation, devices are connected through PLCs that are programmed using the software. Arnab Chakraborty, Tutorials Point Ind. PLCs can be programmed in various ways. There are two textual languages and four grafical languages.

The three most common language structures are: ladder diagram language, Boolean language, and functional chart. Programming Languages. PLCs), but other languages are better suited for some programming applications.

See sample PLC code in five languages. The PLC replaced the relays with a much smaller, more efficient form factor. The electricians working on the relays had to shift skills to working on these computers instead.

An industrial PLC used in a facility. Some manufacturers have common programming languages and some others have dissimilar.

Some of the standard programming languages of PLC are basically of two types, which are further sub-divided into several types, which are as follows: 1. The Statement List (STL) textual programming language enables the creation of hardware-level runtime and memory-optimized user programs. Users are supported by a host of new user-friendly editing functions, including intelligent selection of symbols from PLC tags, databases, and local tags, a clear presentation of even complex program code, and various other convenience functions.

In fact, most of the non-European vendors do not offer this functionality, or only have a very limited spectrum of options, such as Ladder and SFC. The IEC is an international organization that is mandated to prepare and publish international programming standards for all electronic, electrical and related technologies. Another method is state logic, a very high-level programming language designed to program PLCs based on state transition diagrams.

Many early PLCs did not have accompanying programming terminals that were capable of graphical representation of the logic, and so the logic was instead represented as a series of logic expressions in some version of Boolean format, similar to Boolean algebra. Choose any programming language. Mostly Ladder Diagram (LD) programming language is used in the industry.

If you are a beginner, consider LD as your programming language to learn. Later you can choose other programming languages based on your requirement and experience. Computer programming language, any of various languages for expressing a set of detailed instructions for a computer. The earliest programming languages were assembly languages, not far removed from instructions directly executed by hardware.

Although there are many computer languages, relatively few are widely used.

Inga kommentarer:

Skicka en kommentar

Obs! Endast bloggmedlemmar kan kommentera.