This means that it could be useful for environmental clean-ups like oil spills, and the aerogels only need to be picked up later after absorbing the spilled material. This low density, in combination with the hydrophobic properties of graphene sheets, makes graphene aerogel a promising candidate for oil absorption. What makes graphene aerogel so popular is how incredibly lightweight it is.

Scientists in China have created a graphene aerogel that is seven times lighter than air with the ability to be balanced on a single blade of grass. With immense elasticity and absorption, graphene aerogel is considered one of the best materials when it comes to filtration. Nitrogen doped graphene aerogel (NGA) has a 3D nanostructure, large surface area and remarkable mechanical properties.

Reduced graphene oxide can be produced by chemists more easily and cost-effectively than aerogel graphene oxide. But we are sure that chemists will develop suitable methods for the production of graphene oxide aerogel in the future.

A typical example is the aerogels produced by cooling the gelled materials below −°C by a freeze dryer. It is approximately 7. Anti-CO poisoning ability is significant in formic acid oxidation in the fuel cell technique.

Abstract Metal‐organic frameworks (MOFs) have been considered as promising platforms for preparing the efficient oxygen evolution reaction (OER) catalysts, but few of them are directly employed as. Not even a year after it claimed the title of the world’s lightest material, aerographite has been knocked off its crown by a new aerogel made from graphene.

Created by a research team from. The unique well-defined “center-diverging microchannel” dandelion-like structures were observed in the aerogel microspheres and a formation mechanism of the structure, i. The graphene oxide aerogel microspheres were prepared by a novel approach, i. This is the first video in a two part series. I had to split this into two videos because the vacuum pump in my freeze dryer needs some maintenance which sho.

Chalcogel is an aerogel made of chalcogens (the column of elements on the periodic table beginning with oxygen) such as sulfur, selenium and other elements. Metals less expensive than platinum have been used in its creation.

They are commonly low in density and thermal conductivity but make excellent insulators as they are almost completely comprised of gases. GAs are also very elastic but can go back to its complete. When graphene sheets are neatly stacked on top of each other and formed into a three-dimensional shape, it becomes graphite, commonly known as the lead in pencils. Aerogel Technologies LlcAmerican ElementsAspen Aerogel Inc.

Reade International Corp. Graphene 3D Lab Inc. Browse our wide selection of products for your research needs.

Although graphene aerogels (GA) have been attracted great attention, the easy-operation and large-scale production of GA are still challenges. Further, most GA have a monolith-like appearance, limiting their application-specific needs. Herein, we highlight graphene aerogel spheres with controllable hollow structures (HGAS) that are delicately designed and manufactured via coaxial.

Direct foaming from solids is the most efficient method to fabricate porous materials. However, the ideal foaming fails to prepare aerogel of nanoparticles because the plasticity of their solids is denied by the overwhelming interface interactions. Here, we invent a hydroplastic foaming method to directly convert graphene oxide solids into aerogel bulks and microarrays, replacing the prevalent.

It was demonstrated that under simulated sunlight, the graphene aerogel concentrates the sunlight, heating up water to 45°C. As describe graphene aerogel is over 99% by weight, rendering the material highly porous.

A graphene aerogel (GA) with a three-dimensional (3D) structure, ultra-lightweight nature, and high hydrophobicity was simply fabricated by the one-step pyrolysis of glucose and ammonium chloride. How to incorporate graphene with MoS to obtain the high-capacity and stable anode material is still an ongoing task. Our graphene aerogel is different from current aerogels in both microstructures and properties.

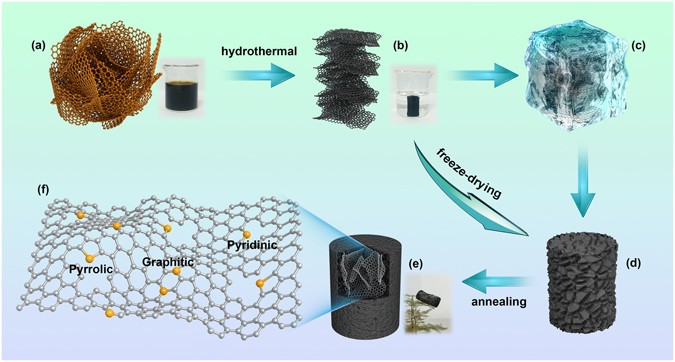

Weighing a minuscule 0. Ah g-can still be achieved. Carbon paper‐supported graphene aerogels are examined as anode electrodes for lithium‐ion batteries, employing a hydrothermal process and a freeze‐drying step.

Triethylenetetramine (TETA) and o ‐phenylenediamine (OPD) prove to promote graphene aerogel formation and its chemical bonding onto the surface of carbon paper. Superelastic graphene aerogel with ultra-high compressibility shows promising potential for compression-tolerant supercapacitor electrode. However, its specific capacitance is too low to meet the practical application.

Herein, we deposited polyaniline (PANI) into the superelastic graphene aerogel to improve the capacitance while maintaining the superelasticity. The aerogel has a high sulfur loading but is nevertheless conducting thanks to the percolating graphene structure.

Inga kommentarer:

Skicka en kommentar

Obs! Endast bloggmedlemmar kan kommentera.